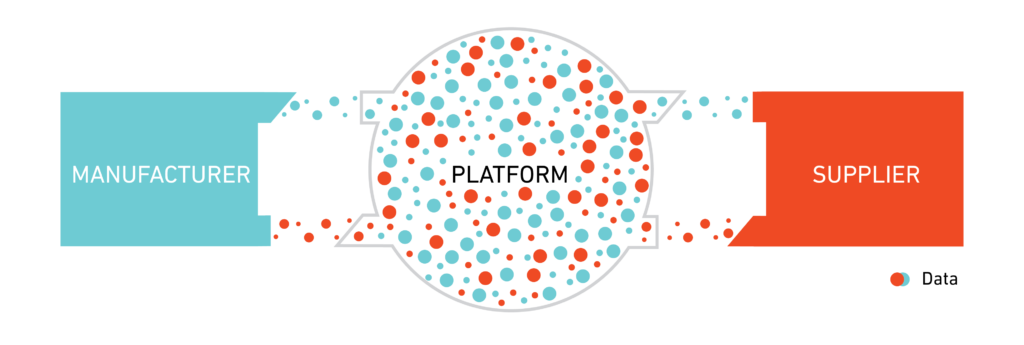

How Manufacturers Can Use Data Platforms to Launch New Profit Centers

Elsie Jamin-Maguire

Manager, Business Consulting

Copy Link

Share on LinkedIn

Share on X

Share on Facebook

Share on WhatsApp